Rubber Sheet Manufacturers

Rubber Sheet Manufacturers and Dealers

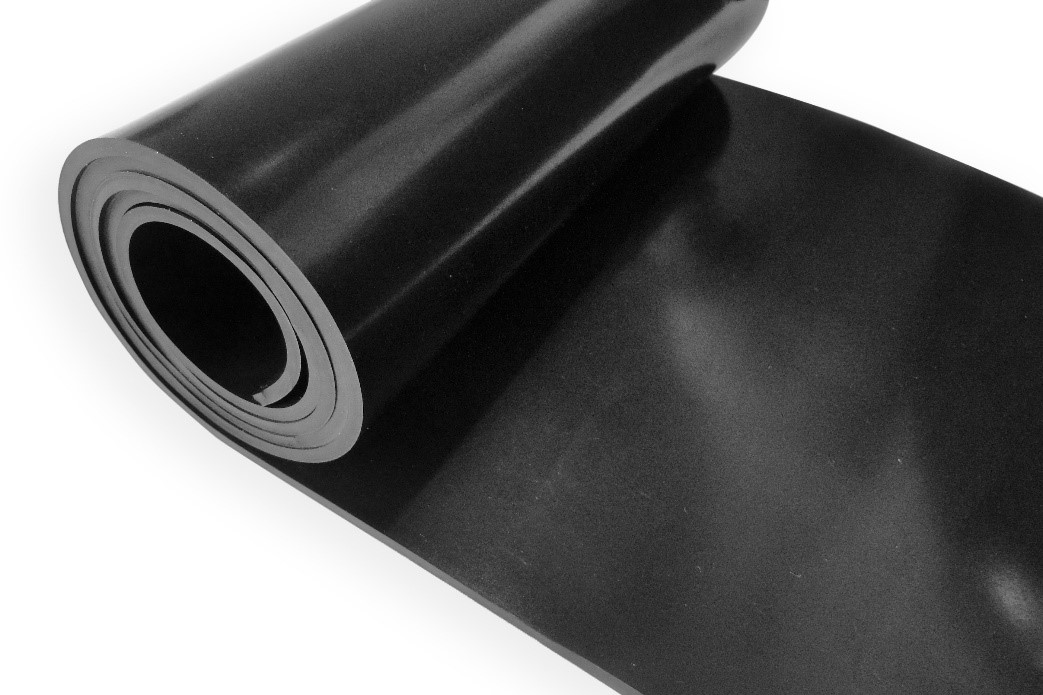

Deesawala Rubber Industries is a leading manufacturer and supplier of Rubber sheets in India which are versatile materials that are used in various applications due to their excellent elastic properties and resistance to wear, tear, and weathering.

Types of Rubber Sheets:

Deesawala Brand Rubber sheets are available in different types based on their composition and properties. Some common types include natural rubber sheets, neoprene rubber sheets, EPDM rubber sheets, Silicone rubber sheets, SBR and Nitrile rubber sheets. Each type has its own specific characteristics and is suitable for different applications.

- Thickness of Rubber sheets : Rubber Sheets come in various thicknesses ranging from 1mm upto 100mm or more based on customer specifications. The thickness you choose depends on the intended application and the level of durability or flexibility required.

- Width and Length of Rubber Sheets: Rubber sheets are typically manufactured in standard widths and lengths. The width can range from a 1meter upto 2 meter while the length can vary from 1 meter length to 10 meter long . Custom sizes can also be obtained based on specific requirements.

- Physical Properties of Rubber Sheets: Rubber sheets exhibit several physical properties that make them desirable for various applications. These properties include high elasticity, good tensile strength, excellent abrasion resistance, resistance to chemicals and solvents, low permeability to gases and liquids, and electrical insulation properties.

- Color and Finish of Rubber Sheets: Rubber sheets are commonly available in black color, which is the natural color of rubber. However, depending on the type and application, rubber sheets can also be found in different colors. The finish of the rubber sheet can be smooth, textured, fabric reinforced, or patterned, depending on the intended use.

- Applications of Sheets : Rubber sheets find extensive use in industries such as Water Infrastructure, automotive, construction, aerospace, electrical, marine, and manufacturing. They are used for gaskets and seals, vibration damping, insulation, conveyor belts, flooring, protective covers, and many other applications that require flexibility, durability, and resistance to environmental factors.

Rubber Sheet Manufacturers in India:

Deesawala Rubber Industries is one of leading rubber sheet manufacturing companies in India which established in the year 1995. With three rubber sheet manufacturing facility in Hyderabad. This makes them the top manufacturers of rubber sheet in Hyderabad.

Technical Specification of Rubber Sheets:

TECHNICAL DATA SHEET FOR RUBBER MATERIAL FOR RUBBER Sheet

TDS NO.: DEESA-01

POLYMER: Rubber

COLOR : BLACK

APPERANCE : SMOOTH

FOR SIZE : As per Customer Specs

| SL. No. | Description | Unit | Specified Value | Test Method | Analysis Report |

| 1. | Hardness | IRHD/Shore A | 60±5 | ISO 48 | 65 |

| 2. | Tensile Strength | MPa | 9 Min. | ISO 37 | 10.5 – 11.2 |

| 3. | Elongation at break | % | 300 Min | ISO 37 | 400 – 500 |

| 4. | Compression Set | ||||

| a) | At 70 ± 2°C for 24 hrs | % | 20 Max | ISO 815 | 11.15 – 12.5 |

| b) | At 23 ± 2°C for 72 hrs | % | 12 Max | ISO 815 | 9.40 – 10.20 |

| c) | At -10 ± 2°C for 72 hrs | % | 50 Max | ISO 815 | 40.50 – 42.5 |

| 5. | Ageing at 70 ± 2°C for 7 days | ISO 188 | |||

| a) | Change in Hardness | IRHD/Shore A | -5/+8 | ISO 48 | +2 to +3 |

| b) | Tensile Strength change | % | -20 Max | ISO 37 | -3.10 to -2. 20 |

| c) | Elongation Change | % | -30 / +10 | ISO 37 | -5 .15 to -3. 25 |

| 6 | Volume change in water at 70 ± 2°C for 7 days | % | -1 / +8 | ISO 1817 | 1.80 – 1.90 |

| 7 | Stress Relaxation at 23°C for 7 Days | % | 15 Max | ISO 3384 | 9.10 |

| 8 | Stress Relaxation at 23°C for 100 Days | % | 22 Max | ISO 3384 | 15.25 |

| 9 | Ozone Resistance at 50 pphm, 40°C for 48hrs | Visual | No Crack | ISO 1431-1 | No Crack |

Note: The above results are conforming to EN 681-1: 1996 and ISO 4633 current standards

Frequent Searches Leading to this page: Rubber Sheet Manufacturers and Dealers, Rubber Sheet Manufacturers, Rubber Sheet Dealers, Rubber Sheet Suppliers, Rubber Sheet.