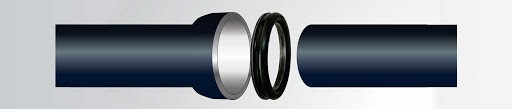

DI PIPE GASKETS

DI Pipe Gasket Manufacturers & Suppliers

Deesawala’s Di Pipe Gaskets are WRAS-approved rubber gaskets suitable for TYTON JOINT DI (Ductile iron) pipelines, fittings and valves. Being the leading Di Pipe Rubber Gaskets manufacturer and dealer, we provide reliable gaskets with flexible joints.

Di Pipe Gasket Feature:

- WRAS and BSEN-681 approved our Tyton Gaskets with PUSH-ON design suit Cast Iron (C. I) and Ductile Iron (D.I.) Pipes.

- WRAS-approved rubber gaskets are strong with flexible joints.

- Di pipe gaskets are applicable in both ‘in the ground’ or ‘above ground’ applications.

- With remarkable resistance to water, ozone, heat, sewerage, chloramines, UV, and abrasion, these gaskets provide exceptional durability.

- Di pipe gaskets are manufactured using EPDM rubber, which improves performance compared to traditional natural rubber.

- Allowing joints to be deflected and permitting axial movement effectively compensates for thermal expansion and contraction.

- Size Range: DN80 – DN1200.

- Relevant Standard: IS:5382, ISO 4633, EN 681, AS 681

TYTON is a revolutionary restrained joint system that can eliminate thrust block, resulting in savings in materials and time. DEESA TYTON is a key to the fast-track design and construction of ductile iron pipeline systems. Di pipe gaskets that we offer have some unique advantages.

Size Range: DN80 – DN1000

Di Pipe Gasket Advantages:

- Di pipe gaskets allow you to construct in RRJ fashion

- Eliminates the need for concrete thrust blocks.

- Speeds up commissioning (no need to wait for concrete curing).

- Streamlines materials sourcing and administration, ideal for weak soils where concrete blocks won’t work.

- Offers 3 to 5 degrees of joint deflection.

- Provides maximum security for strategic mains with fully locked joints.

- Offers an allowable operating pressure (AOP) of 1.6MPa and an allowable site test pressure (ASTP) of 2.0MP. and a maximum allowable operating pressure (MAOP) of 1.92MPa.

- Size Range: DN80 – DN1200

DI Tyton Gasket ® Push-on Gaskets

Deesawala is one of the leading tyton gasket manufacturers in India. The TYTON® Push-On Gasket is used in the TYTON JOINT® Ductile Iron Pipe & Fittings. Push-On Joint (Tyton) of Ductile Iron Pipe holds dual hardness gaskets, which are made from vulcanised synthetic rubber and meet the requirements of the WRAS, BIS, ISO 4633, EN 681 and AS 681

Installation of DI Pipe gaskets

The below link has been provided for the procedure to install the Tyton joint gasket.

Installation of DI Pipe gaskets

The below link has been provided for the procedure to install the Tyton joint gasket.

Available in the following compounds:

| COMPOUNDS: | MAX SERVICE TEMPERATURE: | COMMON USES: | |

|---|---|---|---|

| Water & Sewer | Air | ||

| EPDM | 212°F | 150°F | Vegetable Oil, Alcohols, Dilute Acids, Diluted Alkalis, MEK, Acetone, fresh water, sea water, storm water, sanitary sewage & reclaimed water |

| Nitrile | 150°F | 125°F | Fresh water, salt water, sanitary sewage, storm water, petroleum products, oils, fats, chemicals, greases |

| Neoprene | 200°F | 150°F | Fresh water, salt water, sanitary sewage, storm water, greases |

| FKM | 212°F | 300°F | Fresh water, salt water, storm water, aromatic hydrocarbons, fuels, acids, vegetable oils, petroleum products, and most chemicals and solvents |

Frequently Asked Questions

Frequent Searches Leading to this page: di pipe gaskets manufactures, di pipe gakets, di pipe gakets dealers, di pipe gakets suppliers, di pipe rubber gasket, di pipe rubber gasket manufacturers, di pipe rubber gasket suppliers, di pipe rubber gasket dealers, di pipe rubber rings.