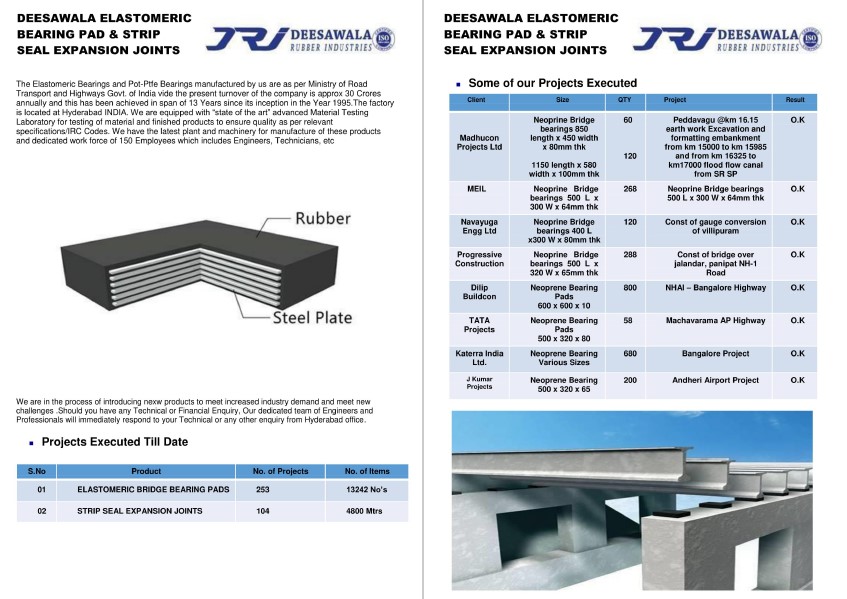

ELASTOMERIC BRIDGE BEARING PADS

Elastomeric Bridge Bearing Pads Manufacturers

Elastomeric Bridge Bearing Pads Suppliers – Company Profile:

Deesawala Rubber Industries is one of the leading manufacturers and suppliers of Neoprene Elastomeric Bearing Pads. As an ISO 9001-2015 certified company, we take pride in being recognized as a prominent manufacturer in the market for Strip Seal Joints, Pot PTFE bearings, Compression Seal Joints, Modular Joints, and Building Joints.

Deesawala Rubber Industries has a well-equipped Material Testing Laboratory for testing the quality of raw materials and finalized products. We ensure the quality standards meet the Industry’s specifications/IRC CODES. And, for manufacturing products, we employ top-notch plant and machinery. Our personnel, who are well-experienced engineers and technicians, work with dedication to meet the specific requirements of our clients.

Elastomeric Bridge Bearing Pad Manufacturers & Suppliers:

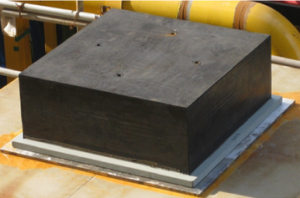

As a leading manufacturer and supplier of Bridge Bearing Pads, and Deesawala Rubber Industries, we always strive to deliver the best products across the industry. Our Neoprene Elastomeric Bearing Pads are designed for easy bridge installation and require zero maintenance compared to other bearings available. We adhere to international norms and standards in the manufacturing process. Plus, the premium quality of materials we use to manufacture our pads makes us a trusted manufacturer of Elastomeric Bearing Pads in the market. Additionally, our products are available at the best price in the market

Elastomeric Bridge Bearing Pads Product Features:

- Cost Effective

- Energy Efficient

- Effective Performance

- Durable

- Superb Quality

Business type of Elastomeric Bridge Bearing Pads Suppliers: Manufacturer/ Supplier.

Areas covered by Elastomeric Bridge Bearing Pads Suppliers Across India.

Frequently Asked Questions

Frequent Searches Leading to this page: elastomeric bridge bearing pads, elastomeric bearing pads manufacturers , Neoprene bearing pads , Bridge bearing pads manufacturers , elastomeric bridge bearing price, fixing of elastomeric bearings for bridges, elastomeric bearing pad specifications, elastomeric bearing pad installation, elastomeric bridge bearing, elastomeric bearing, elastomeric bearing in bridges, elastomeric bearing pad, elastomeric pads, bridge bearing pads,