Duraboard HD 100

Duraboard HD 100 Manufacturers

Deesa Duraboard HD 100 is a Cross-linked Closed-cell Polymer popularly recognised as a compressible Expansion Joint Filler Board. Its flexibility and high compression recovery make it ideal for applications requiring readily compressible, low-load solutions. This filler board is non-tainting, making it suitable for use in structures that retain or exclude potable water, and it contains no bitumen.

Branded as the most compressible filler board for expansion joints, 'Deesa HD100' is a high-performance, cross-linked, pre-moulded, compressible joint filler board. It is a readily compressible filler board that ensures low load transfer. ‘Deesa HD100’ (expansion joint filler board) is a non-bituminous superior alternative to bitumen boards.

Duraboard HD 100 - Advantages

- Virtually no water/moisture absorption

- Durable and resilient

- Outstanding chemical resistance

- Thermal stability (-40°C to +70°C)

- Non-staining, non-impregnated, non-bleeding

- Environmentally friendly

- User-friendly – easily cut with a knife for simple installation

- Rot-proof and resistant to bacteria – no need for external treatment before installation

Duraboard HD 100- Description

Dura board® HD insulation stands out as a high-density board, offering the same high dimensional and surface uniformity level as Duraboard LD insulation. However, it goes a step forward by providing increased compressive strength and a higher modulus of rupture. This increased density is achieved through the inclusion of clay additives during the manufacturing process.

Its higher strength makes Duraboard HD insulation well-suited for applications requiring weight load support, such as backing refractory bricks or covering larger unsupported spans

No Weather Effect:

Polyolefin Expansion Joint Filler remains resilient and distortion-free under low load transfer from wet concrete. Its performance remains unaffected by rain, cold, or heat, making it more versatile than traditional filler sheets

Resilient

Demonstrates 95% recovery after deflection (compression), one of the best features desired for any performed closed-cell filler

Great Chemical Resistance

It doesn't get affected by acids or oils, making it perfect for specific applications

Simplicity

Easy to handle and install, unlike the bituminous filler boards. Minimal handling loss and unaffected by mishandling. Preformed closed-cell filler can be cut into any shape using a regular knife, eliminating the need for special tools or expertise

Stability

They are proven to be rot-proof and bacteria-resistant, eliminating the need for treatments to block microorganisms

Temperature

Our polymer-based joint filler sheets accept a nominal temperature cycle with minimal load transfer. Hence, it doesn't affect the structure

Application

- Water retaining and water-excluding structures.

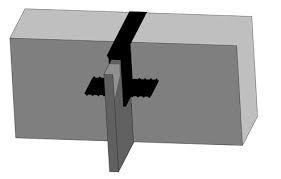

- Structural expansion joints in concrete brick and block work.

- Expansion joints in concrete highways, airport runways, taxi tracks, etc.

- Isolation joints to infill panels.

- Bridge decks, abutments, pier hinge joints, etc.

- Expansion joints in parking areas, industrial flooring, etc.

Closed cell structure

Deesa HD100 sheets boast a deficient water absorption (<0.05%) due to their closed-cell structure, ensuring durability and excellent compression recovery

Bitumen free

No bitumen is used; hence, it is a non-staining product, resulting in trouble-free for the labour force.

| Property/Benefits | Deesa HD100 Dura Board | Bitumen Impregnated Filler Board |

| Manufactured from | Special grade of Polymers | Bitumen + Composites + some additives |

| Product Handling loss | NIL | Considerable, if not careful |

| Structure and implications | Closed Cell Structure and that will not allow water absorption | Not Closed cell structure and that results in very high water absorption |

| Life | Too long | Too short |

| UV stability | Yes | Not sure |

| Resistance to Bacterial /Fungal growth | Yes | No or not sure |

| Weight | Very light | Comparatively heavier |

| Cost to customers | In terms of overall cost, very much economical | More due to shorter life. Life is shorter due to Water absorption, non-UV stability, somewhat brittle type nature. |

| Product sizes | Deesa HD100 boards are available in different sizes to customers to select from: 1200x1800mm, 1500x1600mm, 1000x2000mm & more | Traditionally bitumen impregnated board is produced only in one size normally - 1200mm x 1200mm |

| Stains during applying | Never | Yes, may be. |

| Cutting & Installing | Deesa HD100 is very easy to install | Difficult |

| Compression recovery | > 95% normally. | 70% or less |

| Overall rating | Excellent product with latest approach in enhancing its properties to meet civil engineering’s requirements. | Bituminous joint filler is considered as conventional product and need to rethink to use it for its some drawbacks. |

Compliance

Our Deesa HD100 – expansion joint filler board has proven performance and follows DOT Specifications Part-III, highway Clause 1015 (American), which is evident from the following comparison chart of parameters

| Sr No. | Parameters | Passing Value as per clause 1015 | Deesa HD100 |

| 1 | Compression recovery Minimum | 70% | 95% |

| 2 | Weathering test | No sign of disintegration or shrinkage | No sign of disintegration or shrinkage |

| 3 | Compression extrusion | Free edge does not exceed 6mm | 3.5mm |

Technical Details of Deesa HD 100 Dura Board

| Density | 100 kg/m3 ± 10% |

| Water absorption | 0.080 kg/m2 max |

| Compression deflection and recovery without weathering | Min 94% |

| Compression deflection and recovery with weathering | Min 92% |

| Extrusion | 3mm max |

| Alkali resistance | No effect observed |

| Weather test | No disintegration |

Frequent Searches Leading to this page: dura board hd 100, duraboard hd100, duraboard hd 100 price.