RE Wall Panel Rubber Pads

RE Wall Rubber Pads for Bridges

Molded EPDM Rubber RE Wall Pads

RE wall EPDM Molded EPDM rubber is ideal for outdoor applications because of its ability to resist harsh weather conditions, the reason why it is used in RE Walls for Bridges. Also recommended for its ability to stabilize color and resist heat. EPDM is an economical choice because it offers the advantages of neoprene, at a lower cost. EPDM is widely used in the Construction, Water and automotive industry because it is ozone resistant, temperature resistant and has an attractive appearance.

We do not recommend the use of EPDM for applications that involve petroleum derivatives. Mineral oils and solvents can cause an adverse reaction when used with EPDM.

RE Wall Grooved Rubber Pad Uses

● To avoid vibration on the bridge which absorbs the vibration

● This is avoid cracks in the structure

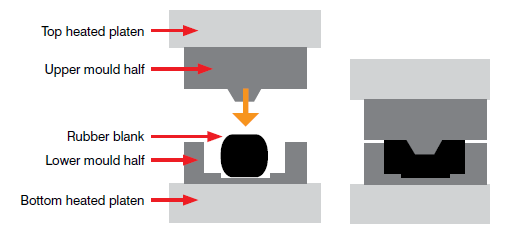

Manufacturing process for RE Wall Rubber in Compression Molding

Deesawala Rubber selects appropriate rubber material based on the product that you need. For controlling the shape and weight of the product, the uncured rubber is preformed and then placed directly into the mold cavity. Once the mold closes, the rubber material compresses between two plates that force the compound to flow, thereby filling the cavity.

The epdm rubber material remains pressed with the right amount of pressure and at the correct temperature, which allows the cure system in the compound to activate. The professional operator overseeing the compression molding process determines the necessary cycle time for the material to cure, thereby reaching the optimal level. With the cycle finished, the molded parts or components get ejected from the mold cavity.

Compared to other processing methods, there are several advantages of compression molding. For example, tooling is typically less complex, making it easier and less expensive to manufacture parts and components. Also, the amount of wasted rubber material is less than with transfer molding or traditional injection molding. Finally, this process is ideal for more cure systems and elastomers. On the downside, preforming rubber requires time and effort that can impact the cost and, in many instances, extend cycle times.

Advantages of EPDM Molding

● EPDM offers exception resistance to UV, ozone, weathering, aging and various chemicals● Ideal for outdoor applications

● Offers stability in extreme high and low temperatures

● Resistance to water and steam

● Low electrical conductivity

● Versatility allowing for use in many industries and applications

● Durability and longevity for continuous use

● Less costly than silicone

RE Wall Panel EPDM Pads – Properties

| S No. | PROPERTIES | Test method | Spec |

| Base polymer | EPDM | ||

| 1 | Hardness (Sh.A) | ASTM D2240 | 85±5 |

| 2 | Tensile Strength (MPa) min. | ASTM D412 | 11mpa |

| 3 | Elongation@ Break (%) min. | 400 | |

| 4 | Heat Ageing@ 70°C/70 Hrs | ||

| Change In Hardness, (Points), max. | ATM D573 | -5+8 | |

| Change In Tensile (%), max. | +/-20% | ||

| Change In Elongation (%), max. | -25 | ||

| 5 | Compression Set @ 70°C/22 Hrs (%) max. | ASTM D 395 Method B | 25% |

| 6 | Resistance to Ozone,Quality Retention rating (%), min. |

ASTM D 1771 | 85 |

| 7 | Water resistance for 70Hrs/100°C, Volume Change, max. (%) |

ASTM D 471 | 10 |

| 8 | Colour | Black | |

| 9 | Density | 1.3±0.03 | |

| 10 | Tear Strength daN/cm | 38 | |

| 11 | Max. Ash Content | <5% |