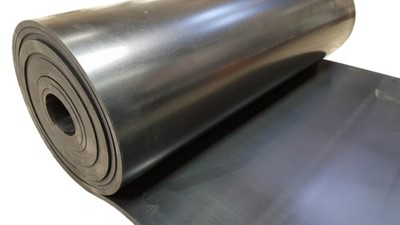

NEOPRENE RUBBER SHEET

Neoprene Rubber Sheet Manufacturers:

Deesawala Rubber Industries stands out as one of the leading manufacturers of Neoprene/Chloroprene Rubber Sheets in India, operating from our manufacturing facility in Hyderabad. We manufacture our Neoprene Rubber Sheets using high-quality materials which can be used in various sectors, including Water infrastructure, Aerospace, Automotive, Pharma, Chemical, Cement, Heavy Engineering, Mining, Fertilizers, and more.

Specification of Neoprene Rubber Sheets

- Durometer: 65 Shore A (+/-5), providing excellent resistance to heat, ozone, weathering, and strong adhesion to metal.

- Specific Gravity: 1.3 g/cm3.

- Elongation at Break (min): 500%.

- Minimum tensile strength: 85 kg/cm2.

- Temperature range capacity: (-25) to (+130).

- Available in standard lengths of 10 meters, 2 meters, and 1 meter.

- Standard width of up to 2 meters.

- Also available in cut pieces of 1ft. to 1 ft. (Up to 4 mm).

- Offered in 10 thickness options (1, 1.5, 2, 2.5, 3, 4, 5, 6, 8, 9, 10) mm.

Ideal for applications such as Neoprene pads, gasket material, seals, and strips, our Neoprene Rubber Sheets ensure reliability and performance across various industries.

TECHNICAL DATA SHEET FOR NEOPRENE RUBBER MATERIAL FOR RUBBER SHEET

TDS NO: DEESA-01

POLYMER: Neoprene Rubber Pad

COLOR: BLACK

APPERANCE: SMOOTH

FOR SIZE: As per Customer Specs

| SL. No. | Description | Unit | Specified Value | Test Method | Analysis Report |

| 1. | Hardness | IRHD/Shore A | 65±5 | ISO 48 | 68-70 |

| 2. | Tensile Strength | MPa | 9 Min. | ISO 37 | 10.5 – 11.2 |

| 3. | Elongation at break | % | 300 Min | ISO 37 | 400 – 500 |

| 4. | Compression Set | ||||

| a) | At 70 ± 2°C for 24 hrs | % | 20 Max | ISO 815 | 11.15 – 12.5 |

| b) | At 23 ± 2°C for 72 hrs | % | 12 Max | ISO 815 | 9.40 – 10.20 |

| c) | At -10 ± 2°C for 72 hrs | % | 50 Max | ISO 815 | 40.50 – 42.5 |

| 5. | Ageing at 70 ± 2°C for 7 days | ISO 188 | |||

| a) | Change in Hardness | IRHD/Shore A | -5/+8 | ISO 48 | +2 to +3 |

| b) | Tensile Strength change | % | -20 Max | ISO 37 | -3.10 to -2. 20 |

| c) | Elongation Change | % | -30 / +10 | ISO 37 | -5 .15 to -3. 25 |

| 6 | Volume change in water at 70 ± 2°C for 7 days | % | -1 / +8 | ISO 1817 | 1.80 – 1.90 |

| 7 | Stress Relaxation at 23°C for 7 Days | % | 15 Max | ISO 3384 | 9.10 |

| 8 | Stress Relaxation at 23°C for 100 Days | % | 22 Max | ISO 3384 | 15.25 |

| 9 | Ozone Resistance at 50 pphm, 40°C for 48hrs | Visual | No Crack | ISO 1431-1 | No Crack |

Note: The above results are conforming to EN 681-1: 1996 and ISO 4633 current standard

Neoprene Rubber Sheets Weight Chart

| Thickness | Units of Measurement | Specific Gravity | Weight Per Sq Meter |

| Neoprene Rubber Sheet 3mm thick | Square Meter | 1.3 | 3.9 kg |

| Neoprene Rubber Sheet 5mm thick | Square Meter | 1.3 | 6.5 |

| Neoprene Rubber Sheet 6mm thick | Square Meter | 1.3 | 7.8 |

| Neoprene Rubber Sheet 8mm thick | Square Meter | 1.3 | 10.4 |

| Neoprene Rubber Sheet 10mm thick | Square Meter | 1.3 | 13 |

| Neoprene Rubber Sheet 12mm thick | Square Meter | 1.3 | 15.6 |

Special Characteristics of Neoprene Rubber Sheet

Neoprene Rubber Sheets are resistant to ageing, acid, alkalies, heat & cold mineral oils.

Usage of Neoprene Rubber Sheet

Besides being resistant to petroleum products like Nitrile rubber sheets, Neoprene sheets are also resistant to temperature ranging from (-) 400°F to (+) 3000°F, acids, alkalies, open flame and also where food grade non-toxic sheets are required.

Frequent Searches Leading to this page: neoprene rubber sheet, Rubber Sheet Manufacturers, Neoprene rubber sheet dealers & manufacturers, EPDM Rubber sheet, neoprene rubber sheet specification, neoprene rubber sheet price list neoprene rubber gasket sheet, neoprene sheet, neoprene rubber sheets suppliers, industrial rubber sheet.