BITUMEN MASTIC PADS

Expansion Joint Filler Board :

Expansion Joint Filler Board:

Deesawala Rubber Industries is the leading manufacturer and dealer of the Deesa Jolly Expansion Joint Filler Board. We manufacture our products with cane fibre. Our high-quality mastic pads stand out as the best in the industry. Infused with Bitumen in various percentages, our pads are the perfect material for expansion joint fillers. By leveraging UK, U.S.A, and Indian standards, we manufacture Expansion Joint Filler Board.

Deesa Jolly Board Expansion Joint Filler:

Being the leading Bitumen Mastic Pads manufacturer, we provide Deesa Jolly Expansion Joint Filler Board. Our products are environment-friendly, high-performance, water-resistant, bitumen-impregnated, and made from cane fibre. We manufacture our products in different sizes, showing effective resistance to compression and remarkable recovery qualities.

Our Bitumen Mastic Pads are specially crafted for use as expansion joint fillers in concrete, brick, block work, and isolation joints.

These are pre-moulded, high-performance joint filler boards. These are designed as closed-cell structures with cross-links. It has an excellent recovery of 95% (after compression up to 50%), making it the ideal choice for this purpose.

Uses

- Roofs & floor finishes: Great to utilise in expansion joints in concrete floors.

- External wall cladding: ideal for filling structural expansion & structural separation joints in block & on-site concrete construction.

- Internal surfaces: Handy for expansion joint filling in various concrete floors, including screed floors with underfloor heating.

- Traffic surfaces: Specially designed for filling expansion joints in motorways, roads, runways, pedestrian areas, bridges, curbs, etc.

- Reinforced concrete structures: Works as joint fillers in piers and lateral supports like abutments.

- Building superstructures: Effective for filling expansion joints in basements, retaining walls, site slabs, subways & other water-excluding structures.

Mastic Pads Advantages

- It is simple to cut, handle and install.

- The closed cell structure ensures the absorption of water or moisture.

- You have the option to use a ShaliBar/Backer rod if desired.

- It has recovered after being compressed.

- It has a resistance to chemicals, including acids, alkaline oil and hydrocarbon.

- It is durable. Does not rot, remaining intact with prolonged use.

- Since it is bitumen free, there are no issues with staining or bleeding.

Mastic Pad Application

- Expansion joint filler strips are commonly used in concrete traffic surfaces such as highways, airports, runways and streets.

- Expansion joint fillers are utilised in reinforced concrete structures like piers, retaining walls and lateral supports such as abutments.

- Expansion joint fillers find application in driveways, aprons, pavements, curbs, gutters and other concrete paving projects.

- Expansion joint fillers provide a gap-filling solution between existing or adjacent constructions and insets in concrete paving like drains or manholes.

- These fillers are employed in various internal finishes, flat works and concrete floors while adhering to the latest industry standards and local regulations.

Physical Properties

Deesa Jolly Board Expansion Joint Fillers conform to the following required standards -

- ASTM -D. 1751-83/D.545 – 84 Testing

- Concrete paving and structural construction’

- Pre-formed expansion Joint Fillers for concrete’

- Department of Transport – London 1986: `specification to highway works, part 3, clause 1015′ B.S. 1142 for Standard Specifications for Expansion Joint Fillers.

- Board Expansion Joint Fillers conform to the following required standards

- IS 1838(Part-I) 1983 Standard Test of Expansion Joint Fillers.

- Strong points and performance characteristics: Compression to 50% thickness in the initial state: - Recovery is 80/84% Weathering and compression to 50% thickness: – Recovery is 70/76%.

- Deesa Jolly Board returns to more than 70% of its original thickness after three applications of pressure sufficient to reduce its thickness by 50%.

- Extrusion: No effect (0.75 mm) Unaffected by temperature changes Low moisture absorption due to bitumen impregnation. Standard Bitumen content 10-20-35%. Other possibilities upon request. Suggested application details for typical joints.

Extrusion

When Deesa Jolly Board is compressed to 50% of its thickness with 3 edges restrained Deesa Jolly Board, when compressed to 50% of its thickness with 3 edges restrained, it shows an extrusion of not more than 1 to 2mm on its free edge.

Compression

Deesa Jolly Board, when compressed to half of its original thickness under an initial load of 689 to 5171 kPa (or 100 to 750 PSi), experiences a weight loss of no more than 0.1 to 0.2%.

(Permitted: less than or equal to 3% by weight).

Durability & Handling

The Deesa Jolly Board is designed to be strong and maintain its thickness and surface finish when subjected to loads and stacking. Because it has been impregnated with bitumen, it doesn't absorb water. This means that it can withstand conditions, leading to its long-lasting durability.

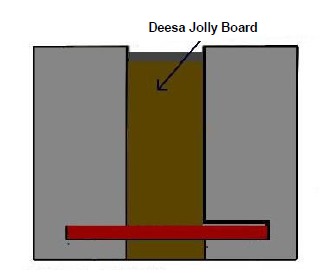

When installing the Deesa Jolly Board, it is positioned flush with the slab. Extends fully into the depth of the slab. It is placed at a depth of ¾ of an inch below the slab's surface. To ensure a watertight seal against pressure, an ideal sealant is applied either at the top or bottom of the joint. Dowel bars are used to maintain alignment between sections of the slab. The Deesa Jolly Board is precisely fabricated to accommodate these dowel bars, and the entire joint assembly is placed before pouring concrete.

Size and thickness of Mastic Pads

4’ x 4’ x 12mm

4’ x 4’ x 18mm

4’ x 4’ x 25mm

4’ x 2’ x 12mm

4’ x 2’ x 18mm

4’ x 2’ x 25mm

Technical Data Sheet of Deesa Jolly Board Expansion Joint Board

| TEST AS PER ASTM D1751 | 25 MM THICK 35% BITUMEN CONTENT |

| 1.Dimension Thickness (mm); | 25M |

| 2. Compression | |

| a. Stress applied for compressing specimen to 50% of its thickness | 2800-3200 KPa |

| b. Loss in Weight after application of Stress | 0.1-0.2 % |

| 3. Extrusion (mm) After compressing to 50% of the specimen's thickness | 0.5mm |

| 4. Recovery (%) 10 minutes after compressing to 50% of the specimen's thickness | 75-80% |

| 5. Density (kg/m3) | 330-350 |

| 6. Water absorption (%) | 15% |

| 7. Asphalt content (%) | 36-37% |

| TEST AS PER ASTM D1751 | 18 MM THICK 20% BITUMEN CONTENT |

| 1.Dimension Thickness (mm); | 18.3 M |

| 2. Compression | |

| a. Stress applied for compressing specimen to 50% of its thickness | 2400-2700 KPa |

| b. Loss in Weight after application of Stress | 0.1-0.2 % |

| 3. Extrusion (mm) After compressing to 50% of the specimen's thickness | 0.5mm - 1mm |

| 4. Recovery (%) 10 minutes after compressing to 50% of the specimen's thickness | 82-85% |

| 5. Density (kg/m3) | 300-330 |

| 6. Water absorption (%) | 50% |

| 7. Asphalt content (%) | 20-23% |

Data Sheet Of Deesa Jolly Bitumen Board as Per British Standard 6093

| Property | Specification | ||

| Deesa Jolly Board | British Standards | ||

| Density Range Kg m3 | 270 TO 300 | 200 TO 400 | |

| Pressure for 50% Compression N mm-2 | 2.5 To 3.8 | 0.7 To 5.2 | |

| Resilience % recovery after compression | 75 To 80 | 70 To 85 | |

| Tolerance to water Immersion | Suitable if immersion is infrequent | ||

Frequent Searches Leading to this page: mastic pad, mastic pad specifications, mastic pad price, bitumen mastic pad, mastic pad suppliers in hyderabad, Bitumen Mastic Pads Manufacturers, Bitumen mastic pad dealers, Expansion Joint filler board , mastic pad uses , 3m mastic pads , 3m 2200 mastic pads , mastic pad for expansion joint , mastic pad size .